Any unauthorized copying, reproduction, modification, or distribution of any part of this content is strictly prohibited without written permission from Newtech Insulation Company Limited. Any violation will be prosecuted to the fullest extent of the law.

Heat is considered one of the significant physical hazards in workplaces. In industrial settings, workers often face heat-related issues from production processes or various machinery. Industries or businesses that involve heat-intensive work include paper pulp production, tire manufacturing, glass and light bulb production, metal smelting, casting, or rolling. Many industrial establishments are seeking solutions to prevent and control heat for worker safety and to reduce heat loss.

Heat Loss and Rising Electricity Costs

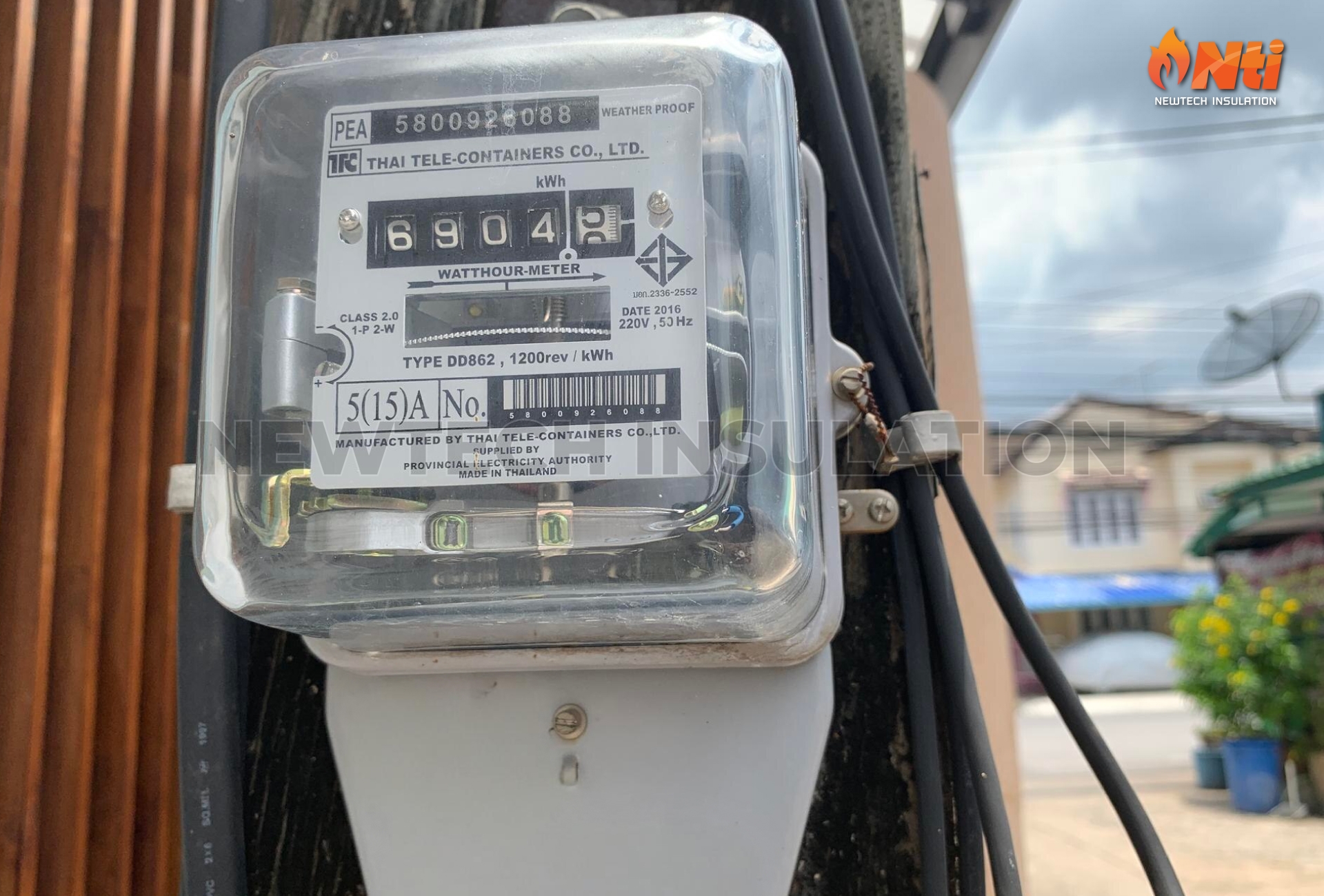

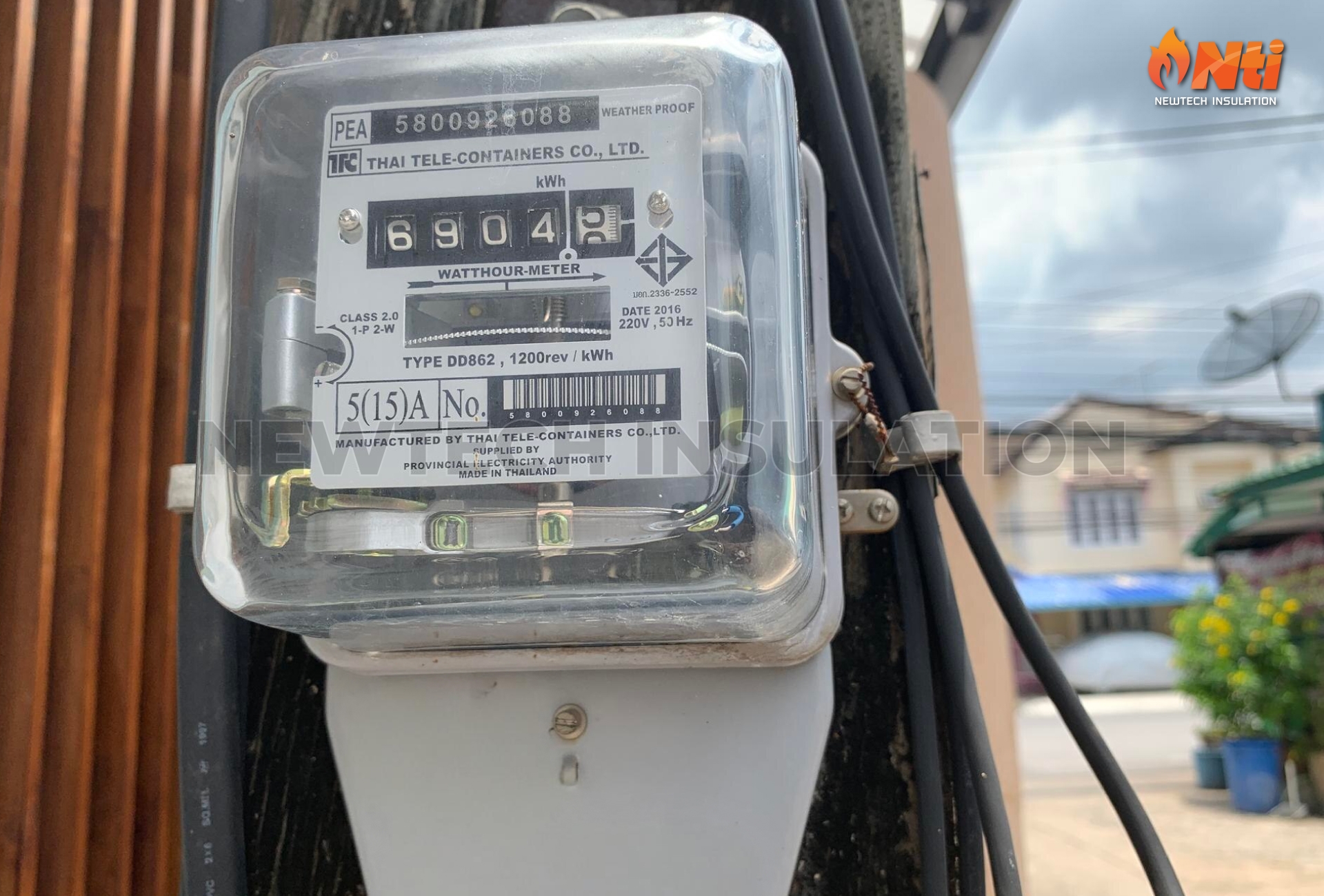

Did you know that “heat” is one of the reasons for “increasing electricity costs”? Electricity rates in Thailand have nearly doubled due to the import of natural gas from abroad and increased electricity demand, especially in the industrial and business sectors.

Heat affects many Thai industries, which are currently facing higher production costs due to significantly increased electricity prices with no signs of reduction. Many industrial plants have heat sources without proper insulation, resulting in heat loss and energy waste. Besides machinery heat, factors contributing to heat generation may include production processes, building design, and ventilation systems, leading to energy loss and higher electricity costs.

Current Situation (October 2022)

When investigating the causes of rising electricity costs, it was found that the increase in the Ft (Fuel Adjustment) charge during 2022-2023 is due to four main reasons:

ZAVE®: A Solution to Heat Loss and High Electricity Costs

ZAVE® energy-saving insulation from NTi helps reduce heat loss problems that contribute to shockingly high electricity costs. This issue can be addressed by using ZAVE® removable insulation, made with standard materials from HKO Germany, which can continuously withstand temperatures up to 1000°C. Its properties include:

ZAVE® insulation can be easily removed for cleaning the machinery inside and reinstalled without complications. Customers can remove and replace it themselves without special tools. Importantly, ZAVE® insulation has a longer lifespan than conventional insulation due to its higher density.

Benefits of ZAVE® Insulation

Conclusion

Rising electricity costs will no longer be a problem when you manage heat loss from industrial production processes easily by choosing ZAVE® energy-saving insulation. This removable industrial insulation effectively helps reduce electricity costs. For assistance in selecting the most suitable insulation for your specific needs or budget, contact NTi’s sales department.

By implementing ZAVE® insulation, industries can not only reduce their electricity costs but also improve worker safety and overall operational efficiency. As Thailand continues to face challenges in energy prices, proactive heat management with solutions like ZAVE® becomes crucial for maintaining competitiveness in the industrial sector.