Any unauthorized copying, reproduction, modification, or distribution of any part of this content is strictly prohibited without written permission from Newtech Insulation Company Limited. Any violation will be prosecuted to the fullest extent of the law.

Problems and Causes

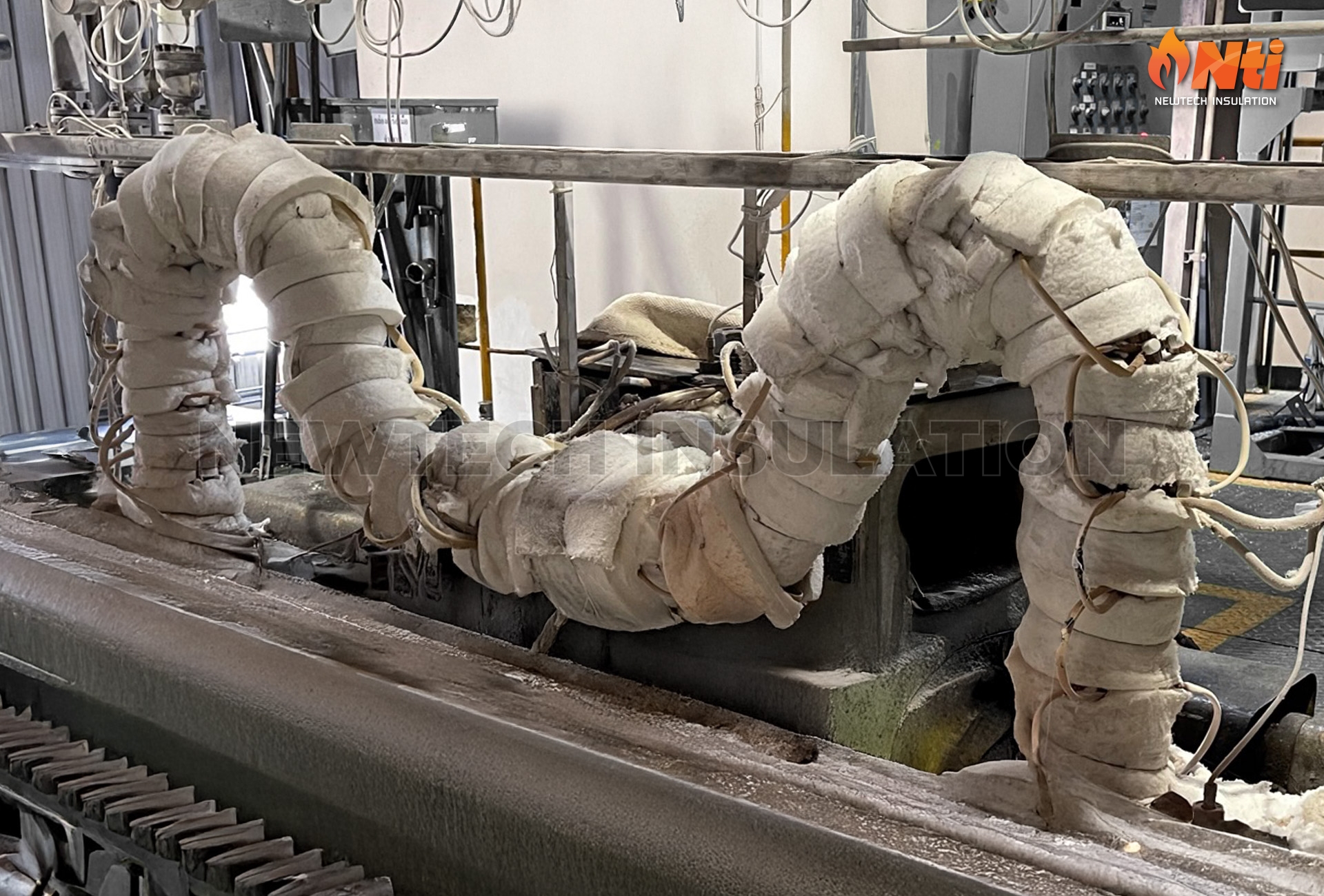

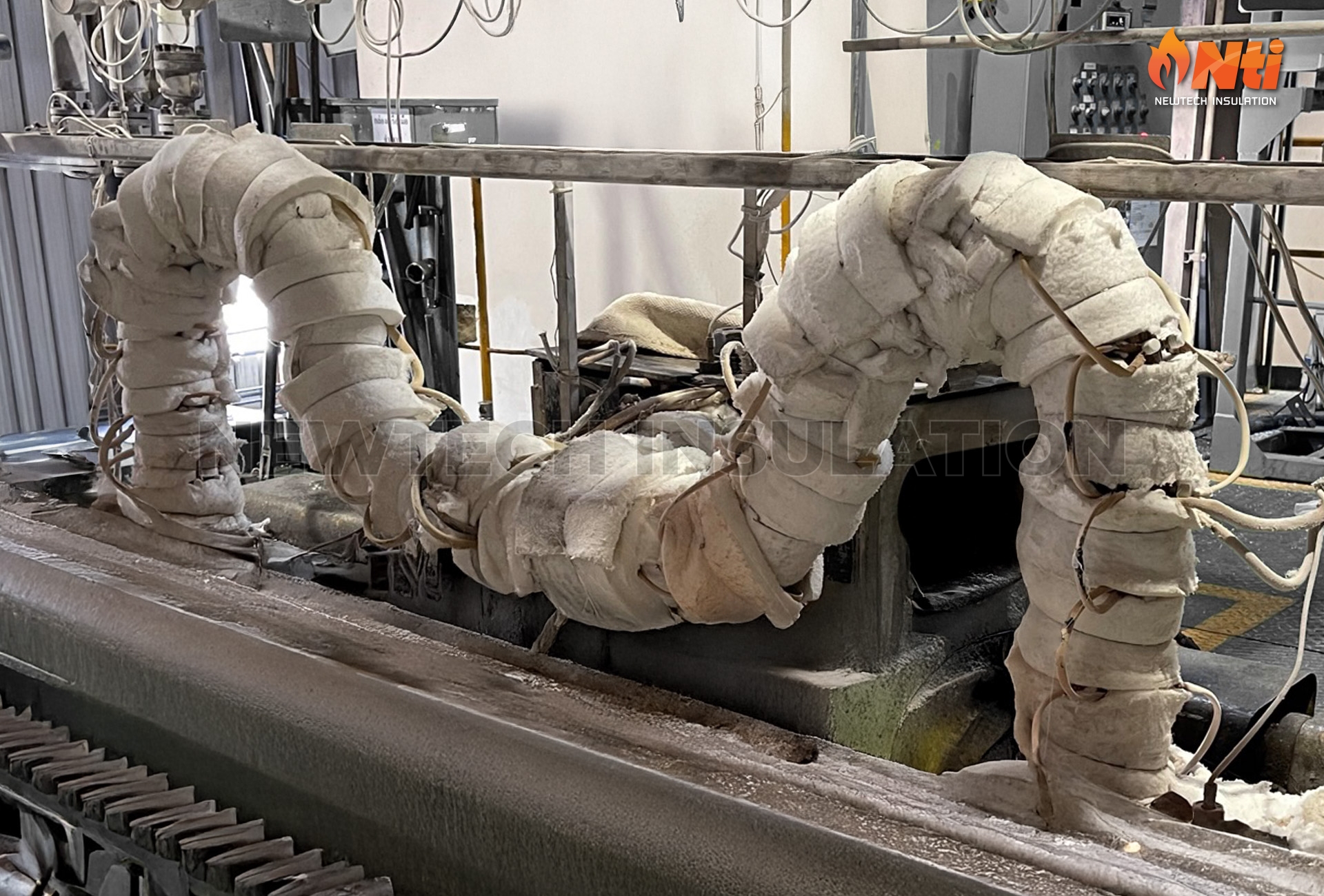

The plastic extrusion machine with diameters of 20 inches and 10 inches, with a total length of approximately 8 m, operates 24 hours per day for 26 days per month. Heat radiates throughout the working area where the machine is installed, causing employees in the area to experience heat stress. This also results in electrical energy waste from the machine’s barrel surface during operation. Initially, users addressed the problem by wrapping and covering the heaters with ceramic fiber thermal insulation, but besides being unsightly, it caused itching and respiratory issues when workers had to handle these materials due to insulation dust inhalation.

Improvement Method

After collecting heat data along the entire length of the Extrusion machine, it was found that the average temperature was 250-285 degrees Celsius, causing the ambient temperature in that area to reach 34-36 degrees Celsius. The energy manager from NTI recommended removing the existing insulation cover and installing removable ZAVE® thermal insulation along the entire barrel length instead. The insulation design must be form-fitting and properly sized for the machine, with water and chemical resistance properties. Users can remove and install it themselves without special tools. Most importantly, it must be free of insulation dust that causes itching and respiratory hazards.

Improvement Results

| Comparison | Extrusion Surface Temperature (Celsius) | Heat Loss/Year (Heat Loss: kW) |

Electricity Cost Loss/Year (Electricity: Baht) |

| Before ZAVE® installation | 283.0 | 178,224 | 641,664.00 |

| After ZAVE® installation | 66.0 | 26,640 | 95,916.00 |

| Reduction | 217.0 | 151,584 | 545,748.00 |