Any unauthorized copying, reproduction, modification, or distribution of any part of this content is strictly prohibited without written permission from Newtech Insulation Company Limited. Any violation will be prosecuted to the fullest extent of the law.

Problem and Causes

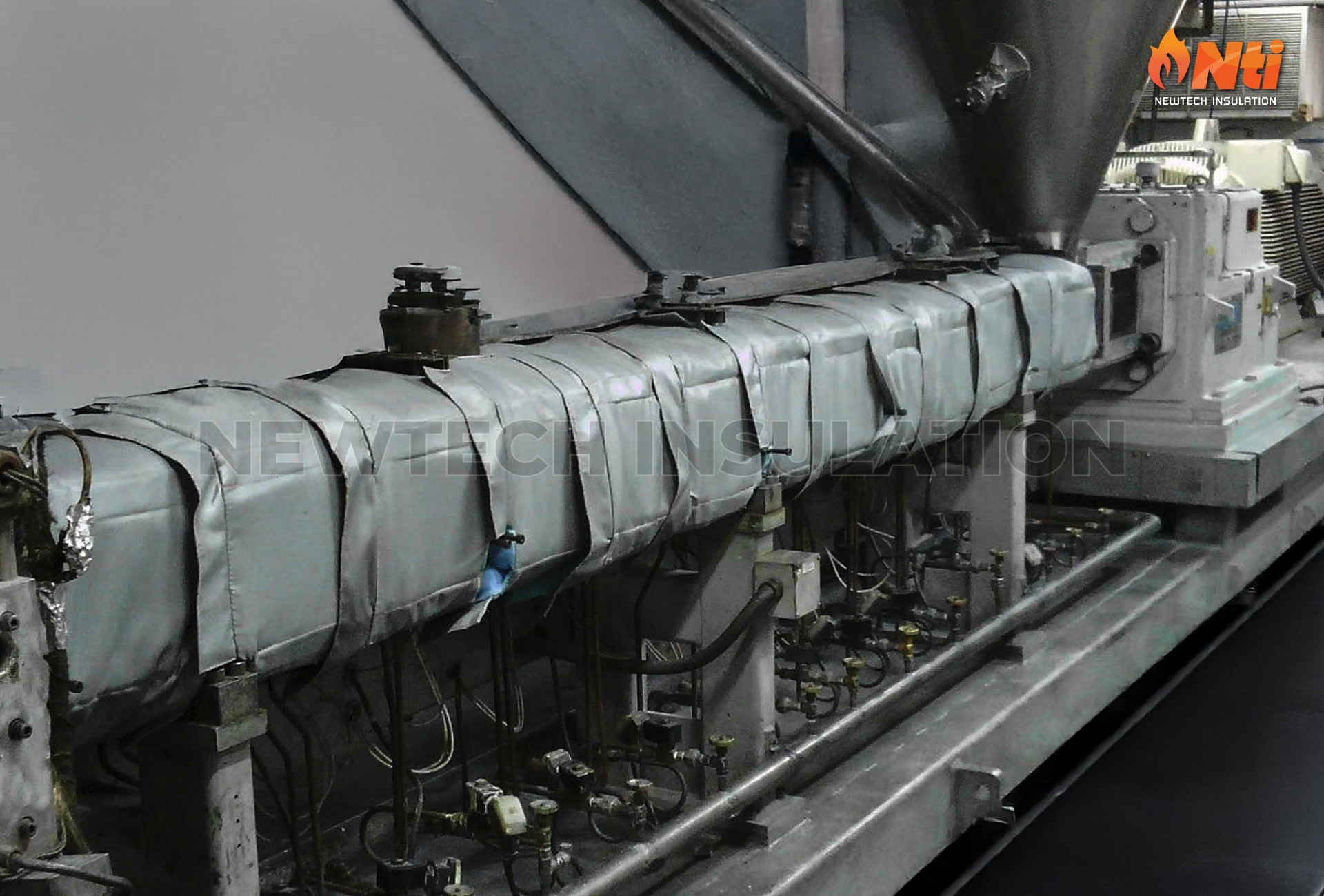

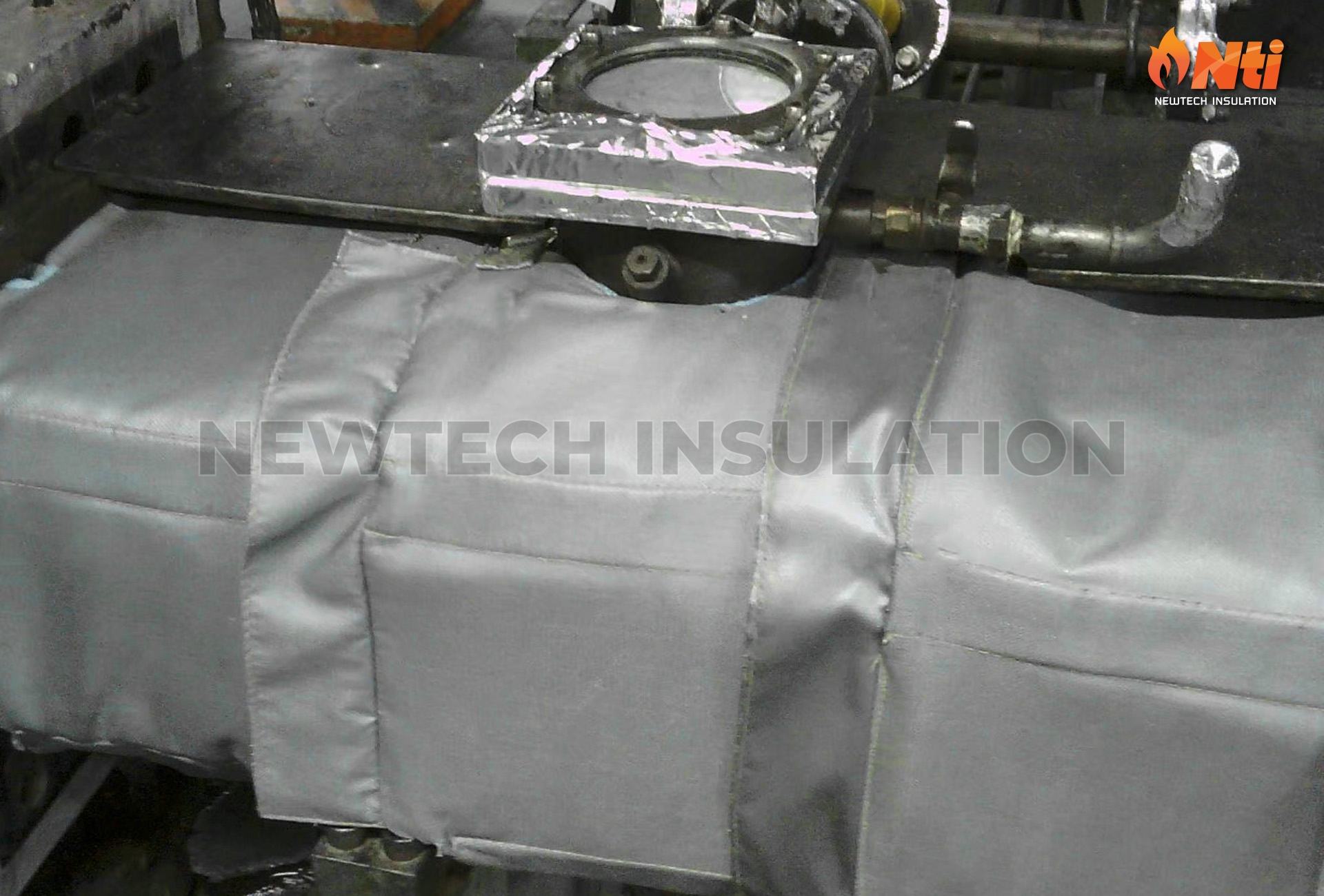

The Extruder is a machine that operates using both mechanical and thermal energy to create pressure and melt raw materials. During its working process, the machine continuously releases heat, causing energy loss when the machine’s surface temperature is significantly higher than the surrounding environment. Heat is continuously transferred to the outside, which means the machine must constantly consume energy to maintain the production process temperature. This issue results in increased electricity costs, which are considered unnecessary production expenses.

Improvement Method

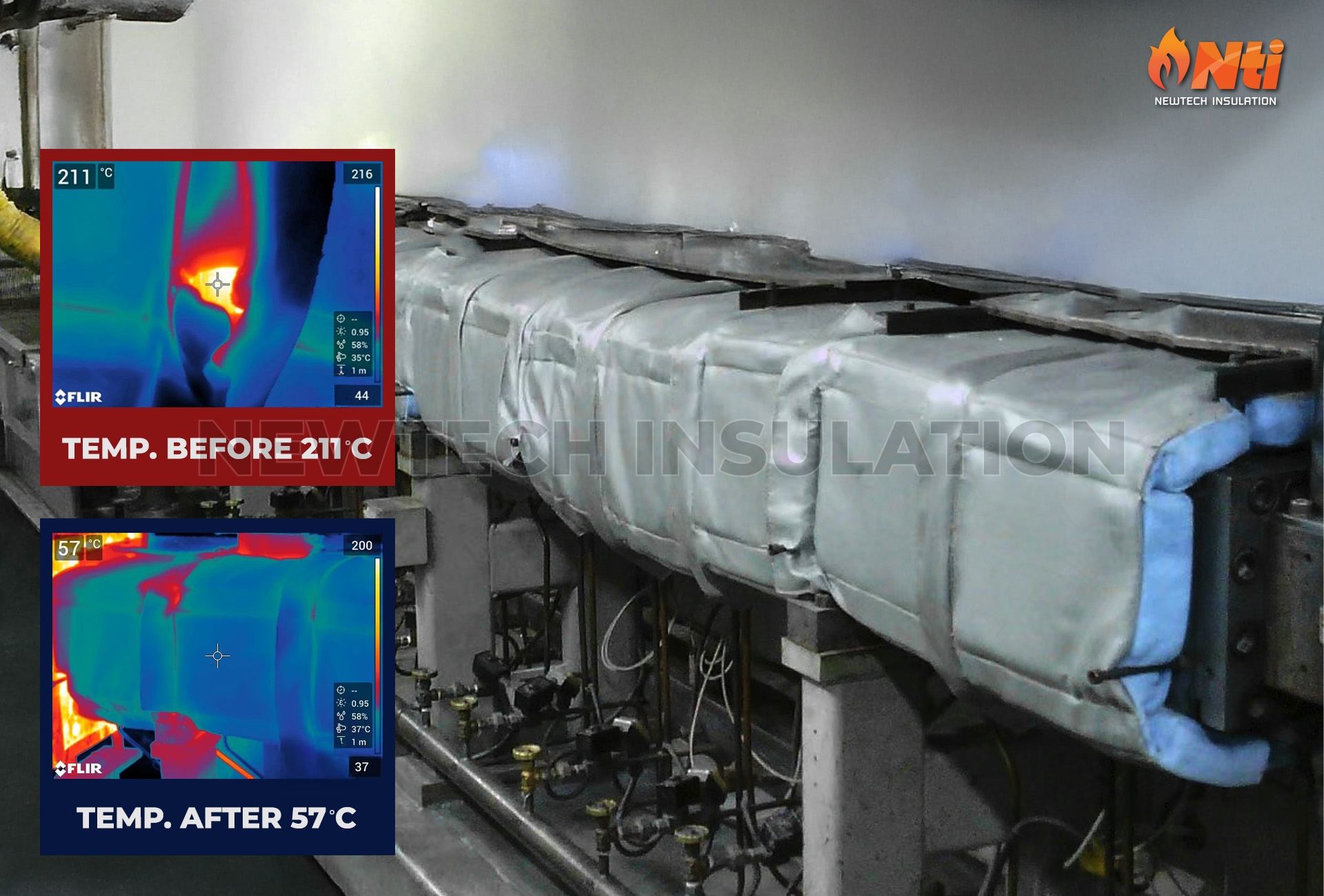

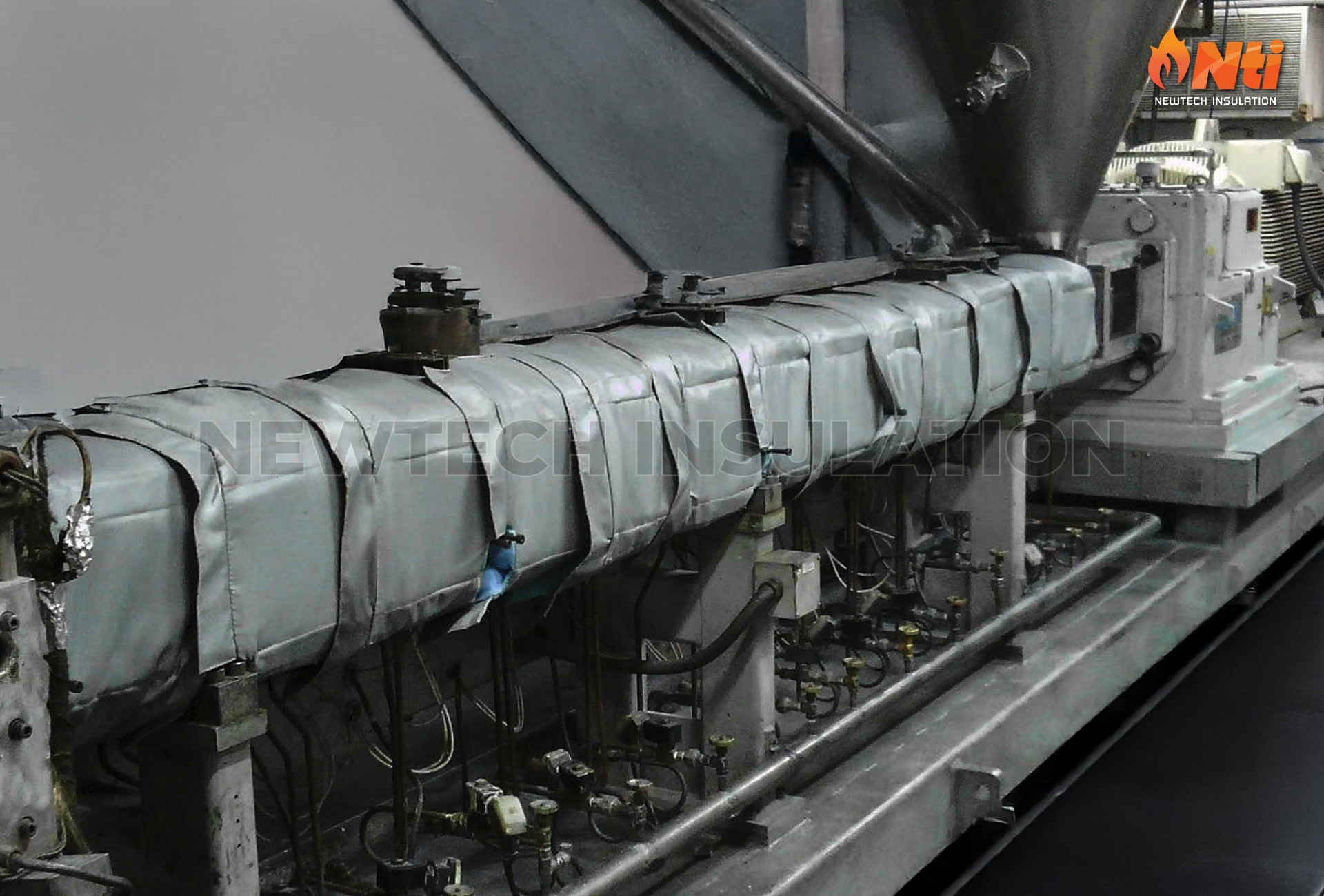

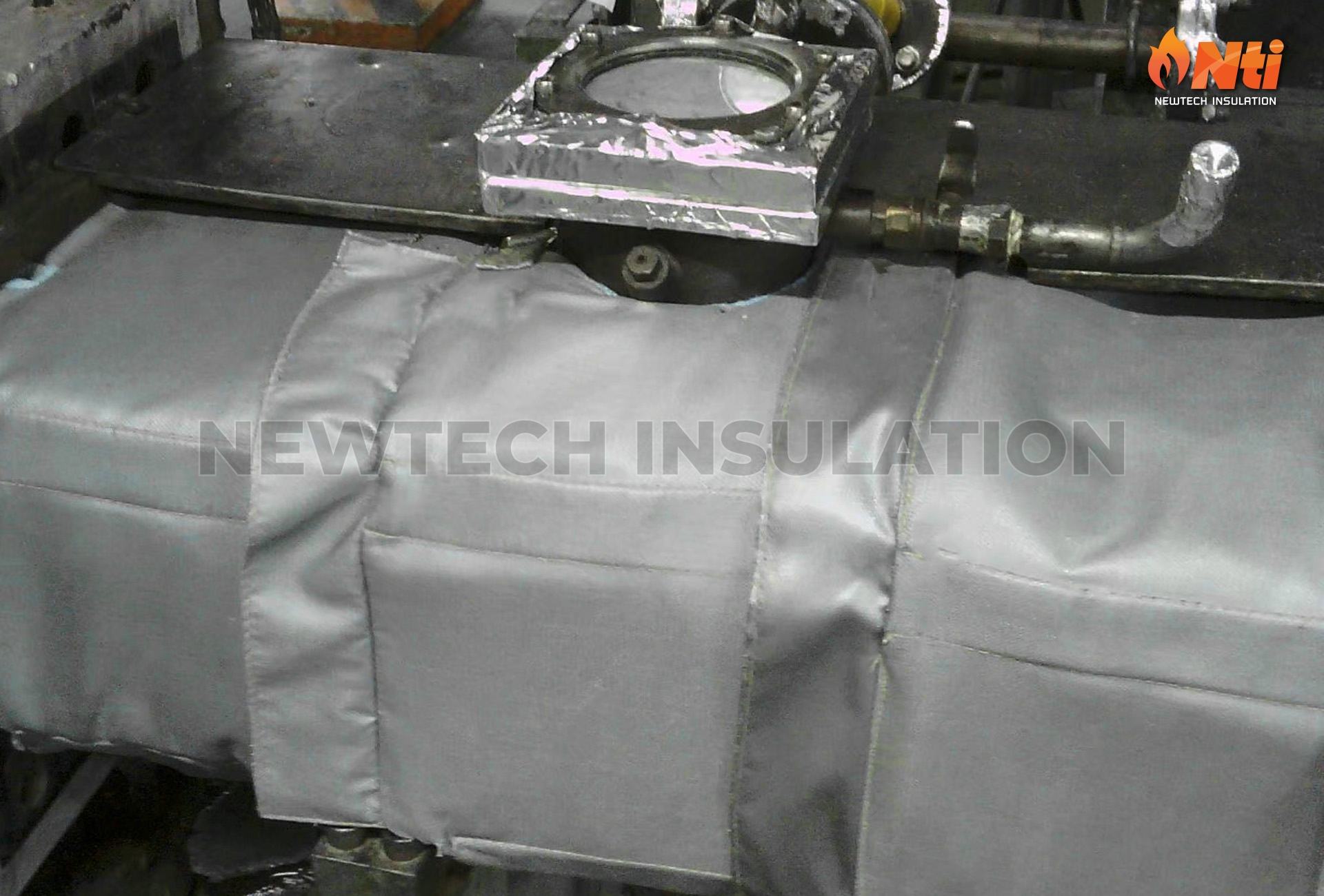

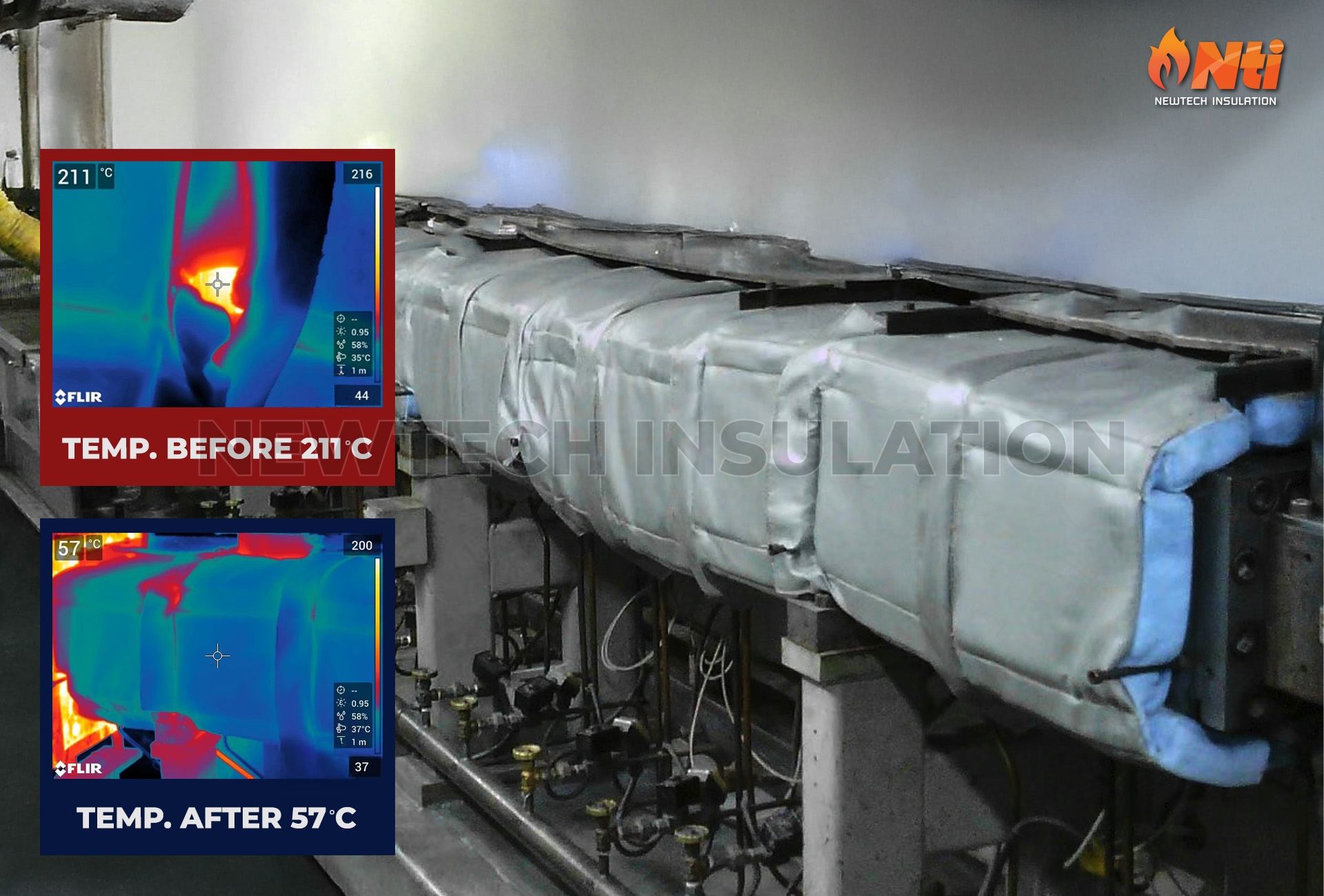

After examination by the NTI team, thermal imaging was conducted at various points on the machine surface, revealing an average surface temperature of approximately 211 degrees Celsius, while the average room temperature was 37 degrees Celsius. To address this issue, NTI recommended using a removable insulation called ZAVE® – specifically designed to reduce heat loss. This insulation solution meets industrial requirements with high-quality materials and a practical design. It can be easily removed and installed, making it ideal for machinery that requires frequent maintenance. The insulation has a long lifespan, capable of withstanding high temperatures and heavy-duty operations, thus providing a valuable investment and an immediate, precise solution to the problem.

Results of the Improvement

| Comparison Table: | Average Heater Surface Temperature (Celsius) | Heat Loss per Year (Heat Loss: kW) | Electricity Cost Loss per Year (Electricity: Baht) |

| Before Insulation ZAVE® | 211 | 5,650.44 | 203,415.84 |

| After Insulation ZAVE® | 57 | 287.77 | 10,359.72 |

| Reduction | 154 | 5,362.67 | 193,056.12 |