For factories or establishments using plastic injection machines, whether installed in general areas or air-conditioned spaces, and wanting to save electricity costs to reduce unnecessary production costs or reduce carbon footprint from the production process, installing removable thermal insulation ZAVE® is another effective option for implementing energy saving projects. Besides durability, aesthetics, and ease of maintenance, it offers the following benefits:

Machines using electrical power in the extrusion process, which is a production process of pushing or pressing materials through a die to create workpieces with a consistent cross-section according to the die shape, face heat loss problems at the machine's heater surface. During operation, the surface temperature averages 180-240 degrees Celsius while the room temperature averages 30-34 degrees Celsius, resulting in energy waste and indirect production costs. Solving this problem with removable thermal insulation ZAVE® offers the following advantages:

Electric conveyor ovens for electronic components, also known as Reflow Soldering Ovens, although equipped with internal thermal insulation from the manufacturer, when used in air-conditioned rooms, the surface temperature is found to be quite high (approximately 60-90 degrees Celsius). This causes air conditioners to work harder, workspace temperatures to be higher than normal, resulting in wasteful electricity consumption for both the reflow oven and air conditioning system. Solving this problem with removable energy-saving insulation ZAVE®, which is designed and manufactured to fit the oven shape with removable sections at frequently maintained points, helps address the following:

Electric rubber molds primarily face the issue of heat radiation from the mold surface during operation. Although many rubber molds come with thermal insulation installed inside the mold cover, when multiple molds are installed in the same area, the heat radiating from each mold surface (70-120 degrees Celsius) combines to create accumulated heat in the workspace. This causes room or building temperature to rise above normal levels (some areas exceed 35 degrees Celsius), exposing workers to heat levels beyond legal limits, resulting in fatigue, increased susceptibility to illness, and reduced work efficiency. This problem can be solved with removable thermal insulation/energy-saving insulation ZAVE® with the following features:

Wave solder pot is a crucial component of Wave Soldering machines, which is a wave-based soldering process used in electronic circuit manufacturing. The wave solder pot or solder pot functions to contain molten solder and create "waves" of solder used for connecting electronic component leads to printed circuit boards (PCB). When the wave solder pot operates in air-conditioned rooms, it causes air conditioning systems to work harder and increases production costs, as the surface temperature of the wave solder pot reaches 60-130 degrees Celsius (depending on brand). However, this problem can be solved by installing ZAVE® thermal insulation with the following outstanding features:

Diesel engines are widely used in various industries due to their durability, simple operating system, easy maintenance, and relatively low fuel costs. Problems arise from heat radiation when diesel engines are used in confined spaces or installed near operators, such as engine rooms in passenger boats, large drilling machine engine rooms, locomotive engine rooms, and road surface milling machine engine rooms. This radiant heat comes from the engine's air intake and exhaust systems, such as turbo, intake manifold, joints, control valves, and exhaust pipes. Installing removable thermal insulation ZAVE® at these points offers the following benefits:

Almost all industrial furnaces for workpiece heating or heat treatment come with refractory materials and heat insulation pre-installed on the inner furnace walls by manufacturers. Initially, the furnace surface temperature doesn't cause problems for operators in the area due to effective insulation. However, after some period of use when the internal insulation deteriorates without repairs, heat from inside transfers to the outer furnace walls, affecting work safety for nearby employees, causing heat loss and unnecessary production costs. This problem can be solved using ZAVE® removable insulation.

In industries where lead melting furnaces are part of the manufacturing process, efficient energy management and heat control are crucial. The installation of ZAVE® removable thermal insulation is a solution that addresses both efficiency and safety requirements. With special properties designed for high-temperature applications, ZAVE® insulation can excellently withstand sudden temperature changes. In addition to operational safety, it offers the following benefits:

The T-Die Heater is a critical component in plastic sheet production processes. Installing proper thermal insulation is therefore vital for operational efficiency and energy conservation. ZAVE® removable insulation is an important solution for managing heat-related issues and energy savings, representing a worthwhile investment that improves production efficiency and creates a safe working environment. Key features of ZAVE® insulation for T-Die Heaters include:

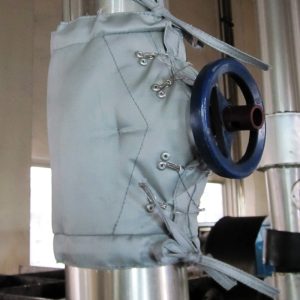

Heat management in industrial valve systems is a significant challenge affecting both production efficiency and energy costs. ZAVE® removable valve insulation offers a solution that meets industrial requirements with innovative designs suitable for all valve types. With superior heat resistance properties compared to conventional insulation, ZAVE® makes industrial heat management simple, efficient, and provides low thermal conductivity. Additionally, it offers the following features:

In industries using burners in their production processes, heat energy loss around the burner surface is a common issue. Heat management and energy conservation are crucial factors for operational efficiency. ZAVE® removable burner insulation addresses both energy savings and safety requirements. Choosing quality burner insulation is therefore a worthwhile investment that helps improve production efficiency and elevate workplace safety standards. The properties of burner insulation include:

Steam pipes are essential equipment for transporting high-pressure steam in industrial facilities. Proper steam pipe maintenance helps improve operational efficiency, save energy, and ensure safe operation. Installing insulation for steam pipes is an effective method for maintaining temperature and reducing heat loss, helping to save energy and improve system efficiency. It represents a worthwhile investment that enhances system performance and reduces long-term operational costs. The properties of steam pipe insulation include: